When your business depends on commercial coolers and freezers, even a small issue can turn into a big headache fast. One temperature dip can spoil inventory, interrupt service, and eat into your profit, and in Bryan and College Station’s Texas heat, the risk is even higher.

The good news?

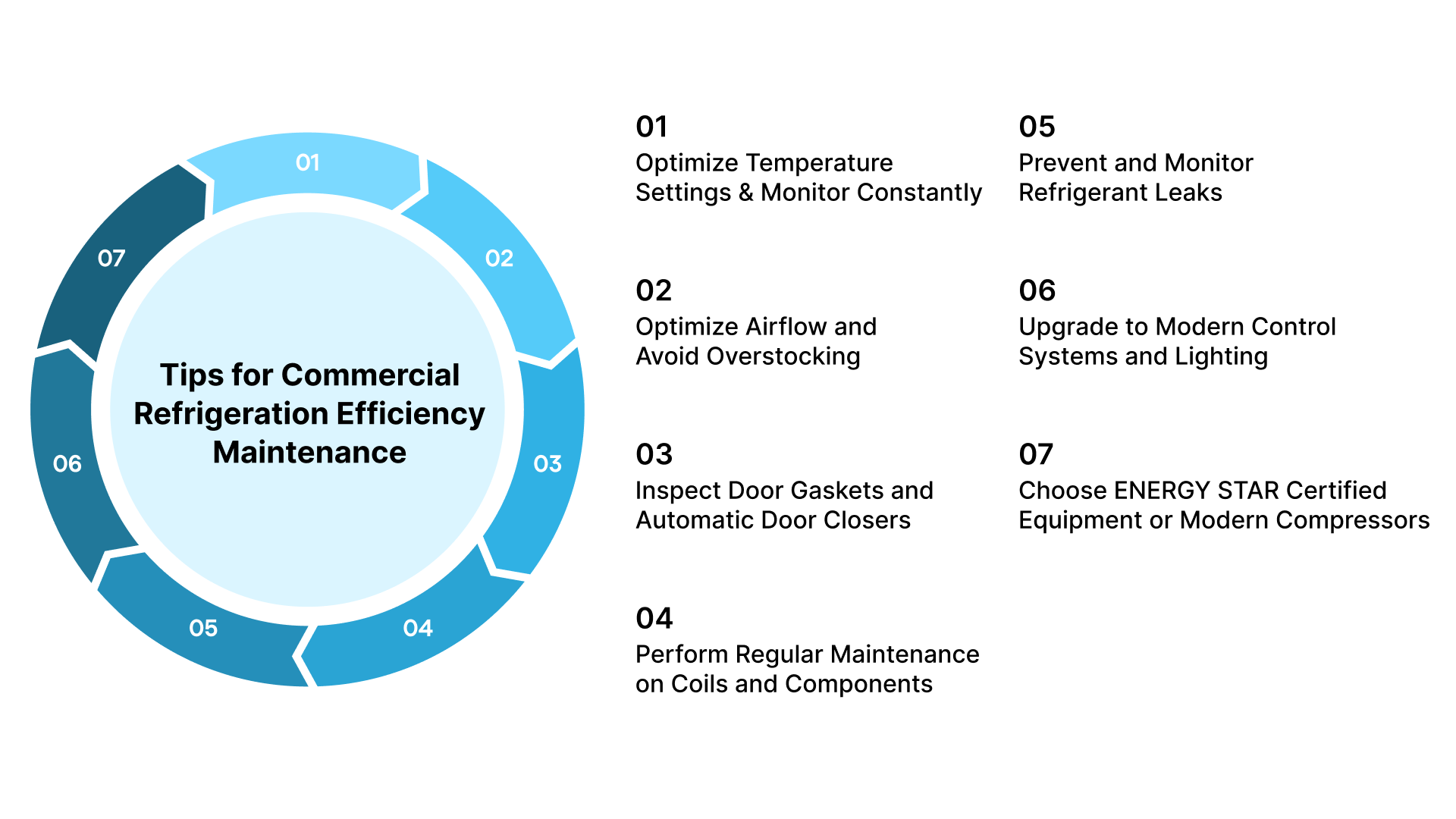

Most breakdowns can be prevented with a little regular care. A few smart maintenance habits can keep your equipment running colder, longer, and with fewer surprises. Let’s go through the key tips that help keep your refrigeration system efficient and worry-free.

Key Takeaways

The most critical step is moving from reactive repair to a proactive refrigeration efficiency maintenance plan that includes regular coil cleaning and leak detection to protect inventory and sales.

Do not overstock units or obstruct external condensers. Both internal and external airflow must be clear for the system to exchange heat efficiently and lower its energy consumption.

Simple operational checks, like replacing worn door gaskets or installing LED lighting, are low-cost, high-impact fixes that drastically improve refrigeration efficiency maintenance by preventing cold air loss and reducing heat load.

Upgrade mechanical controls to smart digital systems and choose ENERGY STAR-rated units with variable speed compressors during replacement to ensure long-term reliability and significant utility savings.

Essential Tips for Commercial Refrigeration Efficiency and Maintenance

To guard against product loss and sky-high utility bills, a proactive approach to refrigeration efficiency maintenance is essential. Below, we provide the practical, expert tips your business needs to keep every walk-in cooler and display case running optimally, even during the peak Texas heat.

1. Optimize Temperature Settings and Monitor Constantly

Setting the correct temperature is basic, but maintaining it consistently is a challenge, especially when units are frequently opened.

Set for Safety, Not Excess: Ensure your walk-in coolers and freezers are set to the minimum safe required temperature for your inventory. Over-cooling by even a few degrees significantly increases energy draw and wear on the compressor.

Implement Digital Monitoring: Manual checks are prone to error. Use calibrated, digital thermometers that are visible inside the unit. Better yet, install smart monitoring systems that alert your staff or management instantly if temperatures drift out of the safe range. This proactive measure prevents a small temperature spike from becoming a costly product loss incident.

Track Door Openings: Excessive door openings are the fastest way to compromise refrigeration efficiency maintenance. Train staff to minimize door time, especially during busy periods or restocking.

2. Optimize Airflow and Avoid Overstocking

Proper airflow is essential for a refrigeration unit to maintain a consistent temperature throughout the entire cabinet.

Respect the Load Lines: Train staff never to stack products past the designated load lines inside display cases or walk-ins. Overstocking blocks the evaporator fan's air path, leading to uneven cooling and forcing the compressor to run longer.

Maintain Clearances: Ensure there is adequate space between the product and the internal walls and floors of the unit. Air needs to circulate freely around every item to achieve maximum cooling effectiveness.

Clear External Obstructions: Make sure the external condensing unit (often located on the roof or outside wall) has clear space around it. Any blockage, from debris to tall grass, restricts necessary airflow and severely hinders the refrigeration efficiency maintenance process.

3. Inspect Door Gaskets and Automatic Door Closers

The smallest crack or misalignment in a gasket can lead to massive energy waste and overwork the unit in the Bryan-College Station heat.

The Dollar Bill Test: Periodically check door seals using the "dollar bill test." Close the door on a dollar bill. If you can pull the bill out easily, the gasket is compromised and needs replacement.

Immediate Gasket Replacement: Cracked, brittle, or torn gaskets allow cold air to leak out and humid, warm air to rush in, creating frost buildup and energy loss. Replacing a gasket is a small investment that dramatically improves refrigeration efficiency maintenance.

Check Closers and Hinges: For heavy walk-in doors, ensure that automatic door closers and hinges are functioning correctly. The door must latch completely on its own every single time to guarantee the integrity of the seal.

4. Perform Regular Maintenance on Coils and Components

Dirty coils are the single biggest killer of refrigeration efficiency maintenance and the most common cause of premature compressor failure.

Clean Condenser Coils: The condenser coils, where the unit releases heat, get clogged with dust, grease, and debris. When dirty, the unit cannot shed heat effectively, causing pressure to rise. This forces the compressor to run hotter and longer, drastically increasing power consumption. These coils require professional cleaning by a technician, especially in greasy commercial kitchen environments.

Clean Evaporator Coils: The evaporator coils, located inside the cold space, absorb heat. If they are frosted over or dirty, they lose the ability to exchange heat efficiently. Regular defrost cycles and ensuring proper drain operation are critical here.

Check Fan Motors and Blades: Inspect evaporator and condenser fan motors. Faulty or slow-moving fans, or bent blades, reduce the necessary airflow across the coils, undermining performance. Technicians should check belt tension (if applicable) and lubricate motors as part of a service plan.

5. Prevent and Monitor Refrigerant Leaks

Refrigerant is the lifeblood of your cooling system. Unlike fuel, refrigerant is not "consumed"; a low charge means there is a leak that must be found and fixed.

Energy and Environmental Impact: Even a small leak causes the system to work harder, leading to higher bills and eventual compressor failure. Additionally, refrigerant leaks are an environmental hazard.

Professional Leak Detection: Refrigeration efficiency maintenance schedules must include professional leak checks. Technicians use specialized electronic detectors, UV dye, or bubble solutions to pinpoint the exact location of the leak.

Repair, Then Recharge: Never allow a technician to simply "top up" the refrigerant without finding and repairing the leak first. This is a temporary fix that guarantees a repeat failure. Central Air & Refrigeration always follows the protocol of find, fix, and then recharge to ensure a durable solution.

6. Upgrade to Modern Control Systems and Lighting

Outdated controls waste energy by relying on simple on/off cycles, and outdated lighting adds unnecessary heat.

Modern Control Systems: Replace old mechanical thermostats with programmable or smart control units. These modern systems offer precise digital temperature control, can log temperature data, and may interface with centralized energy management systems to optimize run times and minimize sudden temperature swings.

Switch to LED Lighting: If your display cases or walk-in units use traditional incandescent or fluorescent lighting, switch to LED bulbs immediately. LEDs use far less electricity and, critically, generate significantly less heat, reducing the thermal load on your refrigeration system. This is a simple win for both lighting and refrigeration efficiency maintenance.

7. Choose ENERGY STAR Certified Equipment or Modern Compressors

When it's time for a replacement or a new installation, the initial investment in energy-efficient technology pays back quickly in reduced utility bills.

ENERGY STAR Certification: Look for ENERGY STAR-certified commercial refrigeration equipment. These units are proven to use less energy than standard models while maintaining performance, and are designed for better insulation and more efficient components.

Variable Speed Compressors: Older systems use fixed-speed compressors that are either fully on or fully off. Modern systems use variable-speed compressors that modulate their output based on the precise cooling load needed. This constant adjustment avoids the high energy spike of starting and stopping, leading to much better efficiency and reduced mechanical stress.

Walk-in Unit Upgrades: For walk-in units, consider upgrading insulation panels and adding strip curtains inside the door opening. Strip curtains create a barrier against ambient air, significantly reducing thermal exchange when the door is opened.

Conclusion

Effective refrigeration efficiency maintenance is the cornerstone of commercial success in the Bryan and College Station area. By implementing smart operational habits and securing professional, local expertise for coil cleaning and preventative service, you proactively mitigate the risk of failure, protect your valuable inventory, and stabilize your operating costs.

Don't wait for a crisis; partner with us today to move your systems from reactive repair to strategic, predictive efficiency.

Ready to secure your commercial refrigeration reliability this season?

Contact Central Air & Refrigeration today for a proactive maintenance consultation and ensure your business stays cool and compliant.

Frequently Asked Questions (FAQs)

Q1. Why is the compressor running constantly, and what should I check first?

A continuously running compressor is a sign of inefficiency. First, check that the door is sealing properly and that the unit is not overstocked. The most common technical cause is a dirty condenser coil that prevents heat dissipation, forcing the compressor to work non-stop.

Q2. How often should I have commercial refrigeration coils cleaned?

For high-volume commercial operations, especially restaurants or bakeries with grease in the air, condenser coils should be inspected and professionally cleaned at least two to four times a year. Retail or non-food service coils may require cleaning less often, but seasonal maintenance is always recommended.

Q3. What is the "dollar bill test" for door gaskets?

The dollar bill test is a quick check for cold air leaks. Close the unit door on a dollar bill. If the bill slides out easily, the gasket is worn or misaligned and needs to be replaced immediately to ensure proper refrigeration efficiency maintenance.

Q4. Is it better to repair an old walk-in unit or replace it completely?

The decision hinges on the age and efficiency of the compressor, the cost of the repair, and the state of the insulation. If the unit is over 10–15 years old, uses an outdated refrigerant, or has consistently high running costs, replacement with an ENERGY STAR model often offers a better long-term return on investment.