The AC compressor is often called the heart of an air conditioning system because it drives the entire refrigeration cycle. When it fails, cooling performance drops sharply or stops altogether. According to the U.S. Energy Information Administration (EIA), air conditioning accounts for nearly 12% of total household energy use in the United States, meaning a malfunctioning compressor can significantly increase operating costs and strain the entire system.

This guide breaks down what causes compressor failure, how to diagnose it, and the full AC compressor replacement process, helping homeowners and property managers make informed decisions.

Key Takeaways

The AC compressor is the core of your cooling system, and failure leads to warm air, high bills, and reduced system efficiency.

Early symptoms such as loud noises, breaker trips, or ice on refrigerant lines indicate pressure or electrical issues that require immediate attention.

Major causes of compressor failure include low refrigerant, dirty coils, electrical problems, moisture in lines, and poor lubrication.

Replacement requires certified tools, EPA-compliant refrigerant recovery, vacuuming, leak testing, and precise charging — not a DIY task.

Costs range from $1,200–$3,000, depending on compressor type, tonnage, refrigerant, and whether the system is under warranty.

Central Air & Refrigeration provides expert diagnostics, professional compressor installation, and maintenance plans to protect your system year-round.

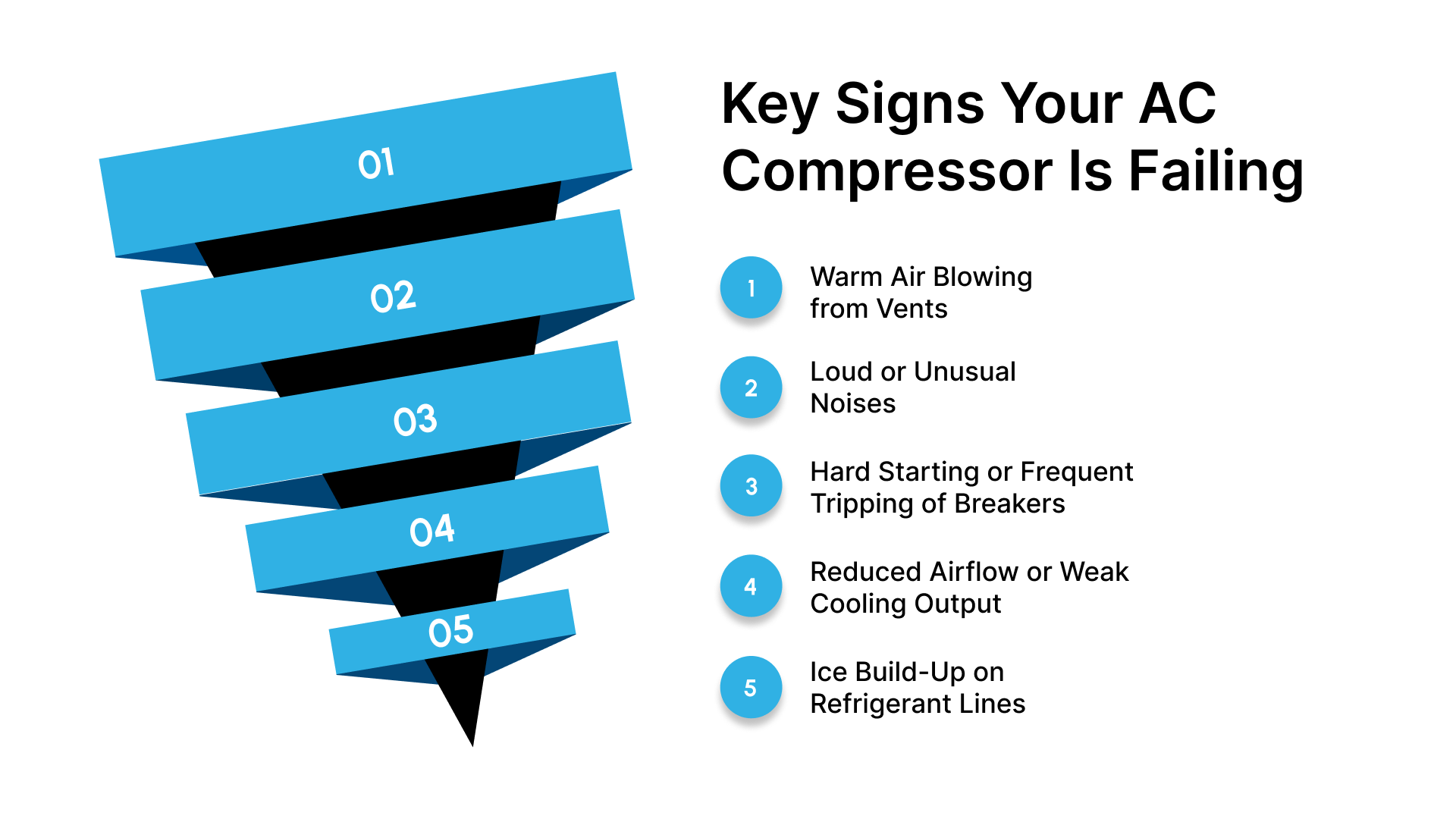

Key Signs Your AC Compressor Is Failing

A failing AC compressor rarely stops working without warning. Most units show clear symptoms that indicate pressure issues, electrical faults, or mechanical breakdown. Identifying these early can save you from a full system failure and costly emergency repairs.

Warm Air Blowing from Vents

If the compressor cannot circulate refrigerant properly, your AC will blow warm or room-temperature air even when the thermostat is set to cool.

Loud or Unusual Noises

Grinding, clunking, or rattling sounds often signal internal compressor damage, worn bearings, or failing motor components.

Hard Starting or Frequent Tripping of Breakers

A compressor that struggles to turn on, or repeatedly trips the circuit breaker, may be drawing excessive electrical current due to internal failure.

Reduced Airflow or Weak Cooling Output

Weak airflow or slow cooling can indicate pressure loss, blocked refrigerant flow, or compressor inefficiency.

Ice Build-Up on Refrigerant Lines

Ice on the copper lines or outdoor condenser can mean the compressor is failing to maintain correct pressure levels.

Here is a table for you to understand the severity of the situation:

Symptom | What It Indicates | Severity Level |

Warm air blowing from vents | Compressor cannot circulate refrigerant → loss of cooling | High |

Loud grinding, rattling, or buzzing noises | Internal mechanical damage, worn bearings, or failing motor | High |

Hard starting or delayed startup | Excess electrical load or weak compressor moto | Medium–High |

Breaker tripping frequently | Compressor drawing too much current (electrical failure) | High |

Weak airflow or slow cooling | Pressure imbalance or compressor inefficiency | Medium |

Ice on refrigerant lines or condenser | Restricted flow or failing compressor causing improper pressures | High |

High indoor humidity | Compressor unable to remove moisture effectively | Medium |

Now that you know what symptoms to watch for, let’s explore the main causes behind AC compressor failure.

The Most Common Causes of AC Compressor Failure

Understanding why compressors fail helps prevent repeat breakdowns and ensures your new unit lasts as long as possible. Most failures trace back to avoidable issues like lack of maintenance, overheating, or low refrigerant.

Low or Leaking Refrigerant

When refrigerant levels drop, the compressor must work harder to pump gas through the system. This added strain causes overheating and eventually burns out the motor.

Electrical Failures

Faulty wiring, damaged capacitors, or corroded terminals prevent the compressor from receiving stable power. Over time, irregular voltage can cause permanent motor damage.

Dirty Condenser Coils

Clogged coils trap heat inside the system. When heat cannot escape, pressures increase, forcing the compressor to overwork until it fails.

Blocked or Restricted Refrigerant Lines

Dirt, moisture, or debris inside the refrigerant circuit can block flow, leading to pressure imbalance and overheating.

Poor Lubrication or Contaminated Oil

Oil circulates with the refrigerant. If it becomes acidic or contaminated, compressor bearings wear prematurely, causing internal friction and failure.

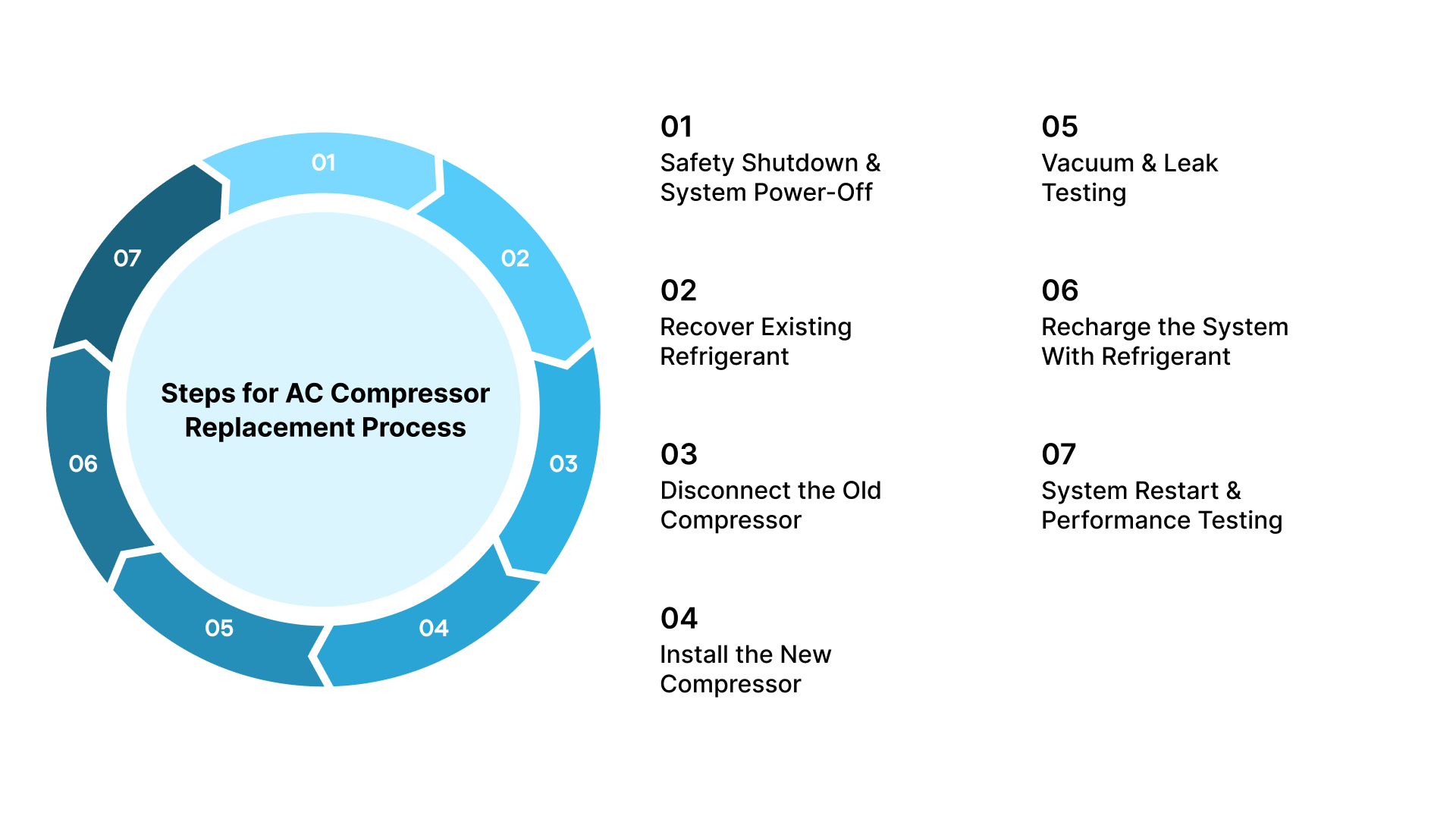

A Step-by-Step AC Compressor Replacement Process

Replacing an AC compressor is a detailed procedure that requires proper tools, certifications, and safety steps. Here’s a clear breakdown of what the process looks like when handled by a trained technician.

Safety Shutdown & System Power-Off

The technician disconnects electrical power at the breaker and verifies the system is completely inactive. This prevents electrical shock and protects sensitive components during service.

Recover Existing Refrigerant

Using EPA-approved recovery equipment, all refrigerant is safely removed from the system. Venting refrigerant into the air is illegal and harmful to the environment, so recovery is mandatory.

Disconnect the Old Compressor

The technician removes mounting bolts, disconnects electrical wiring, and detaches suction and discharge lines. This step requires precision to avoid damaging surrounding components.

Install the New Compressor

A compatible replacement compressor is mounted securely, reconnected to the refrigerant lines, and rewired according to manufacturer specifications. At this stage, technicians also replace critical components such as:

Filter drier

Contactor

Capacitor (if required)

Vacuum & Leak Testing

The system is evacuated using a high-powered vacuum pump to remove air and moisture. After evacuation, technicians perform pressure tests to ensure there are no leaks in the lines or new connections.

Recharge the System With Refrigerant

The AC system is charged with the proper refrigerant type and quantity based on manufacturer guidelines. Correct charging is essential for efficiency, cooling performance, and long-term compressor health.

System Restart & Performance Testing

Finally, the system is powered back on and monitored to verify correct pressures, stable cooling, proper amperage draw, and smooth compressor operation.

Now that the replacement process is clear, it’s important to understand which tools and safety equipment are required for the job.

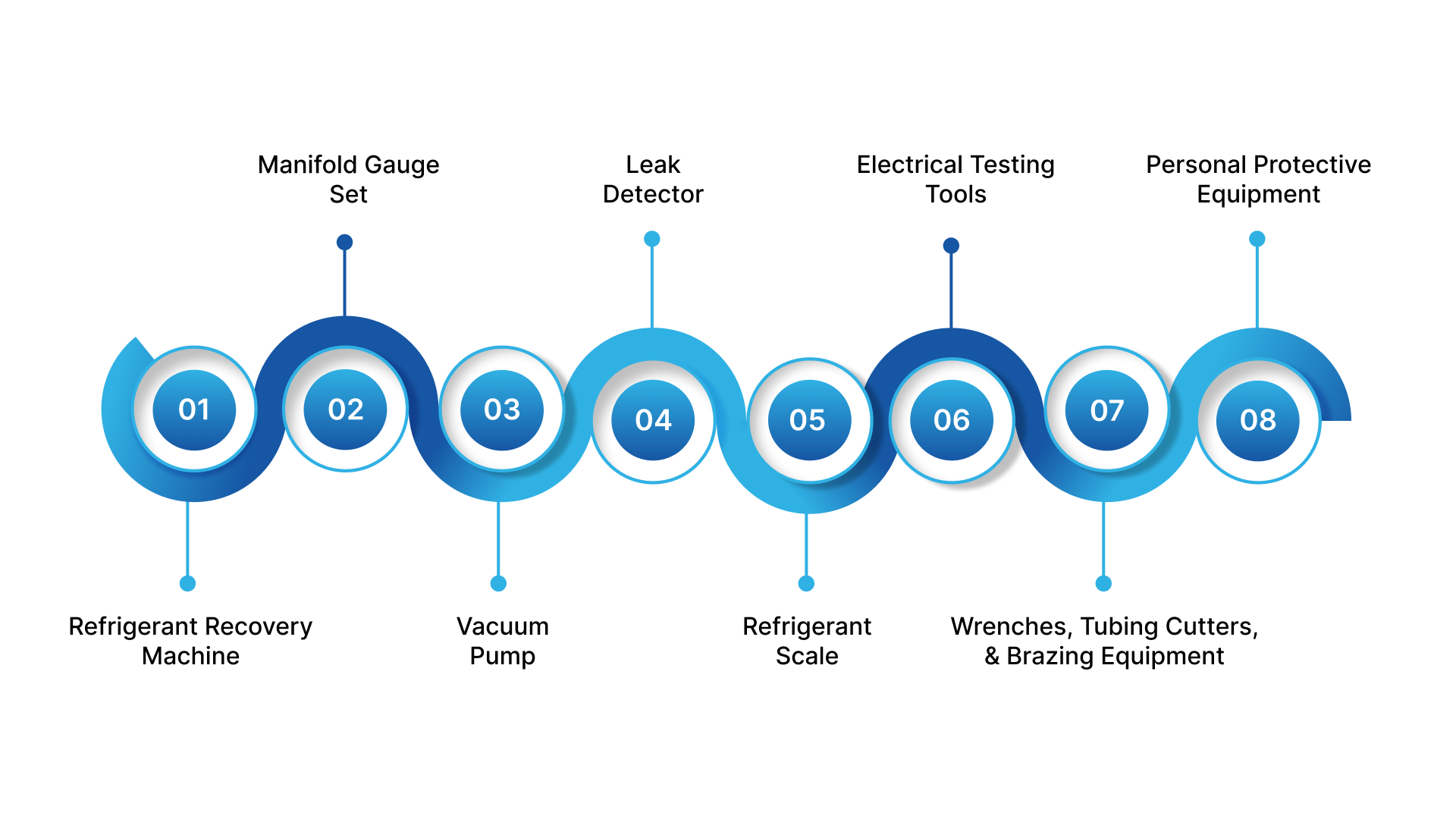

Tools & Safety Equipment Needed for AC Compressor Replacement

Replacing an AC compressor requires specialized HVAC tools and safety gear. Using the right equipment ensures the job is done correctly, safely, and in compliance with EPA regulations. This is one of the main reasons compressor replacement should never be treated as a DIY task.

Refrigerant Recovery Machine

This EPA-approved device safely removes refrigerant from the system before replacement. Venting refrigerant into the atmosphere is illegal, so recovery is essential.

Manifold Gauge Set

Technicians use manifold gauges to measure system pressure, monitor refrigerant levels, and ensure accurate charging after installation.

Vacuum Pump

A high-quality vacuum pump removes moisture and non-condensable gases from the system, preventing future damage to the new compressor.

Leak Detector

Electronic leak detectors help identify any refrigerant leaks in the suction, discharge, or service lines before the system is recharged.

Refrigerant Scale

Used to measure the exact amount of refrigerant added back into the AC unit. Proper charging is critical for efficiency and compressor longevity.

Electrical Testing Tools

Multimeters and clamp meters verify that electrical components, wiring, and amperage readings fall within safe operating ranges.

Wrenches, Tubing Cutters, and Brazing Equipment

Technicians need professional tools for disconnecting lines, securing fittings, and performing any necessary brazing on copper tubing.

PPE (Personal Protective Equipment)

Safety gear protects technicians from injury during installation, including:

Safety goggles

Insulated gloves

Steel-toe boots

Long-sleeve clothing

Respiratory protection (when required)

Tool/Equipment | Purpose |

Refrigerant recovery machine | Safely removes refrigerant; required by EPA regulations |

Manifold gauge set | Measures system pressure and monitors refrigerant levels |

Vacuum pump | Removes moisture and non-condensable gases from the system |

Electronic leak detector | Detects refrigerant leaks before recharging the system |

Refrigerant scale | Ensures accurate refrigerant charging (prevents under/overcharging) |

Multimeter & clamp meter | Tests electrical components, voltage, and amperage draw |

Tubing cutter & brazing equipment | Used to disconnect and reconnect copper lines |

PPE (goggles, gloves, protective clothing) | Protects technicians from burns, cuts, and electrical hazards |

With the tools and safety steps covered, the next section explains how choosing the right compressor can impact long-term performance and energy efficiency.

Choosing the Right AC Compressor Replacement

Selecting the correct compressor is just as important as installing it properly. The wrong type or size can lead to efficiency loss, higher energy bills, and premature failure. Here’s how professionals determine the right match for your AC system.

Match the Compressor to the System Type

Commercial and residential AC units typically use one of three compressor types:

Reciprocating compressors

Scroll compressors

Rotary compressors

Types of AC Compressors & Their Characteristics

Compressor Type | Pros | Cons | Best For |

Reciprocating | Durable, cost-effective | Noisier, less efficient | Older or budget systems |

Scroll | Quiet, highly efficient, modern standard | Higher upfront cost | Most residential + commercial units |

Rotary | Compact, reliable | Lower efficiency for large loads | Small–mid sized AC systems |

The replacement must match the original design specs for compatibility and performance.

Check Tonnage & Cooling Capacity

Compressor tonnage determines how much cooling the system can deliver. Undersized or oversized compressors cause:

Short-cycling

Excessive wear

Uneven cooling

Higher electricity usage

Professionals always match compressor tonnage to manufacturer specs (e.g., 2-ton, 3-ton, 5-ton units).

Verify Refrigerant Compatibility

Modern systems often use R-410A, while older units may use R-22 (now phased out). Using the wrong refrigerant type can permanently damage the new compressor.

Consider OEM vs. Aftermarket Compressors

OEM (Original Equipment Manufacturer):

Perfect compatibility, longer life, factory-tested.Aftermarket:

Cheaper, but may have variations in performance or life expectancy.

For long-term reliability, HVAC technicians often recommend OEM parts.

Evaluate Age of the Entire AC System

If the system is older than 10–12 years, replacing the compressor alone may not be cost-effective. In many cases, upgrading the entire outdoor unit or full system saves more money long-term.

AC Compressor Replacement Cost & Warranty Rules to Know

Replacing an AC compressor is one of the biggest repair decisions homeowners face, and understanding the cost factors helps you avoid unnecessary expenses and choose the right long-term option.

Average AC Compressor Replacement Cost

The cost depends on AC size, brand, and whether the system uses R-22 or R-410A refrigerant.

Residential AC compressor cost: $1,200–$3,000 (parts + labor)

Variable-speed / two-stage compressors: Usually on the higher end

Older R-22 systems: More expensive due to discontinued refrigerant supply

Labor alone often ranges from $500–$1,000, depending on system complexity.

Factors That Influence Pricing

Several variables affect final cost:

System tonnage (2–5 ton units vary significantly in price)

Brand (Carrier, Trane, Lennox, Goodman, etc.)

Type of compressor (single-stage, scroll, variable-speed)

Warranty status

Refrigerant type and additional repairs needed (capacitors, contactors, coils)

If the unit is older than 12–15 years, replacing the entire system may be more cost-effective than replacing just the compressor.

Compressor Warranty Coverage

Most manufacturers offer:

5–10 year compressor warranties on parts

Labor NOT included, unless you purchased an extended warranty

Registration within 60–90 days of installation for full warranty benefits

A failed compressor may be covered under warranty, but you still pay labor and any required refrigerant or component replacements.

When Replacing the Entire AC System Makes More Sense

Buying a new compressor is not always the smartest financial choice. Replacement is often better if:

Your system is 10–15+ years old

The unit uses R-22, making refrigerant expensive and parts outdated

There are other failing components (coil leaks, poor airflow, electrical issues)

Your energy bills have been climbing steadily

The cost of the compressor exceeds 40–50% of a full system replacement

A new unit delivers better efficiency (SEER2 ratings), quieter operation, and lower long-term energy use.

How to Make Your New AC Compressor Last Longer

A new compressor is a major investment, so protecting it with the right maintenance habits helps extend its lifespan and maintain system efficiency.

Clean or Replace Air Filters Regularly

Dirty filters restrict airflow, forcing the compressor to work harder and run hotter. Replace or clean filters every 30–60 days during peak cooling months.

Schedule Coil Cleanings at Least Once Per Year

Dirty condenser or evaporator coils reduce heat transfer and cause high operating pressures—two major factors that shorten compressor life.

Ensure Proper Refrigerant Levels

Too much or too little refrigerant leads to overheating, reduced efficiency, and early compressor failure. Regular testing ensures proper system balance.

Keep the Outdoor Unit Clear of Dirt and Vegetation

Leaves, weeds, and debris block airflow around the condenser. Maintain at least two feet of clearance around the outdoor unit for optimal performance.

Schedule Annual Professional Tune-Ups

A yearly inspection keeps pressure, temperature, airflow, and electrical components in check—critical factors for preserving compressor health.

Conclusion

Your AC compressor is the heart of your cooling system, and keeping it in top condition directly impacts comfort, efficiency, and long-term performance. A proper diagnosis ensures you never replace the compressor unnecessarily, and following a structured replacement process helps restore your system safely and effectively.

With consistent maintenance and timely tune-ups, you can extend compressor life, reduce energy costs, and avoid unexpected breakdowns, especially during peak Texas heat.

Ready to protect your cooling system? Schedule your AC compressor diagnostic with Central Air & Refrigeration today. Book your service before peak season arrives.

Frequently Asked Questions

1. Is it worth replacing just the AC compressor?

It depends on the system age and overall condition. If the AC unit is under 10 years old and in good shape, replacing just the compressor is often cost-effective. If the system is older or has recurring issues, a full system replacement may offer better long-term value.

2. How long does an AC compressor last?

Most AC compressors last 12–15 years with proper maintenance, clean coils, correct refrigerant levels, and regular professional tune-ups.

3. What causes an AC compressor to burn out?

Common causes include:

Low or leaking refrigerant

Overheating due to dirty coils or blocked airflow

Electrical issues such as failing capacitors or contactors

High internal pressure from poor maintenance

Contaminants or moisture in the refrigerant lines

Preventive care is key to avoiding compressor burnout.

4. Can I run my AC with a bad compressor?

No. Running the AC with a failed or failing compressor can damage other components, including the condenser fan motor and electrical system. It may also cause complete system failure.

5. How do I know if my compressor or capacitor is bad?

Compressor symptoms:

Loud clicking, buzzing, or grinding

Overheating

AC blowing warm air or no cooling

Capacitor symptoms:

AC struggles to start

Humming sounds from the outdoor unit

Intermittent cooling or sudden shutoffs

A professional diagnostic can confirm the exact cause and prevent unnecessary replacement.