When it comes to keeping your home or business comfortable and your utility bills under control, skipping HVAC maintenance isn’t an option. In the United States, air conditioning alone accounts for roughly 12% of household electricity usage.

That may not sound like much until you consider how much that adds up over a year, especially in a hot, humid climate. Yet many HVAC systems are treated like “set-and-forget” utilities until something breaks.

The reality: a well-maintained HVAC or refrigeration system doesn’t just keep your space cool or warm; it runs more efficiently, lasts longer, reduces breakdowns, and often delivers real savings.

If you’re a homeowner trying to beat the Texas heat without high bills or a business owner who depends on reliable cooling and refrigeration, this guide is for you. Before minor issues start costing you more than they should, it helps to understand what proper HVAC maintenance really looks like.

At a Glance

Planned maintenance delivers 5–20% annual energy savings: A proven efficiency gain compared to reactive repairs, based on 2025 industry data.

Most breakdowns start as avoidable issues: Simple problems like clogged coils or low refrigerant escalate only when routine checks are skipped.

Commercial downtime creates measurable losses: HVAC or refrigeration failures can lead to revenue drops, product spoilage, and operational delays.

Early system warnings signal declining capacity: Signs like nonstop cycling, weak airflow, or breaker trips help determine when repair is no longer cost-effective.

Professional tune-ups cover 8–12 critical checkpoints: These inspections stabilize performance, extend lifespan, and reduce long-term ownership costs.

Central Air & Refrigeration delivers maintenance built for real system demands: The proactive checks help keep HVAC units efficient, reliable, and trouble-free year-round.

HVAC Maintenance Isn’t Optional: Here’s Why

What most people don’t realize is how much an HVAC system changes over time. Staying proactive isn’t just about avoiding breakdowns; it’s about keeping the equipment running the way it was meant to, reducing unnecessary waste, and making smart decisions before anything becomes a real issue.

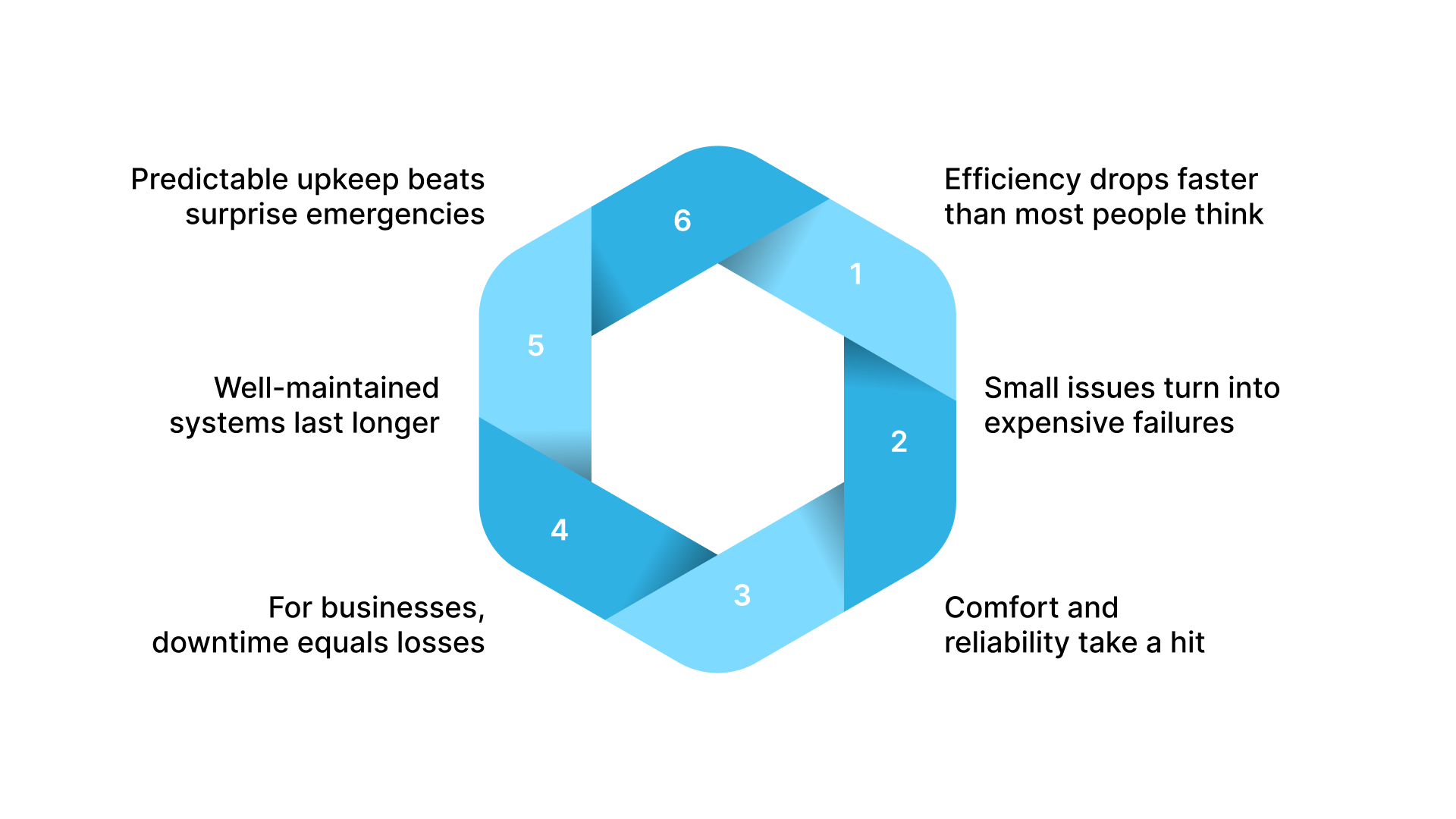

Here’s a clear look at the real, day-to-day reasons HVAC maintenance deserves a spot on your priority list:

Efficiency drops faster than most people think. Dust, clogged filters, worn parts, and restricted airflow can push your system to work much harder than it should. That means higher energy bills for homes and rising operating costs for businesses.

Small issues turn into expensive failures. A loose connection, a low refrigerant level, or a blocked drain line may not look urgent until it becomes a major repair. Most breakdowns start as preventable problems that routine checks would’ve caught early.

Comfort and reliability take a hit. Poor airflow, uneven temperatures, and systems cycling on and off are all signs of a unit under strain. Ignoring them usually leads to sudden failures at the worst possible time, typically during peak heat or cold.

For businesses, downtime equals losses. Restaurants, retail stores, offices, and facilities can’t afford HVAC or refrigeration problems. A few hours of equipment downtime can mean unhappy customers, interrupted operations, or spoiled products.

Well-maintained systems last longer. Keeping coils clean, parts lubricated, and components checked helps equipment run closer to its original performance. That translates to fewer emergency calls and a longer lifespan overall.

Predictable upkeep beats surprise emergencies. Regular tune-ups keep your system stable and give you visibility into upcoming repairs, instead of forcing you into costly last-minute fixes or off-hours service calls.

Once you look at the bigger picture, it helps to understand what proper upkeep really involves behind the scenes.

What HVAC Maintenance Actually Covers?

Maintenance isn’t a single “service”; it’s a set of inspections and actions that keep each part of an HVAC or refrigeration system doing its job. Think of it as a systematic tune-up: some checks are quick and should be done monthly, while others are seasonal or annual and require a certified technician.

The goal is simple: confirm each component is within manufacturer specs and functioning efficiently so you can make informed, cost-effective decisions.

To put it into perspective, here’s what a well-rounded HVAC maintenance routine actually includes.

Filter Check & Replacement: Keeps airflow consistent and prevents strain on the system.

Coil Cleaning (Condenser & Evaporator): Improves heat transfer so the unit can cool efficiently.

Refrigerant Level & Leak Check: Ensures the system is charged correctly and avoids compressor damage.

Electrical Connections & Safety Controls: Confirms wiring, relays, and sensors are secure and functioning.

Blower, Fan & Motor Inspection: Maintains proper airflow and reduces wear on moving parts.

Thermostat Calibration: Aligns temperature readings and ensures accurate cycling.

Condensate Drain & Pan Cleaning: Prevents blockages, overflow, and moisture-related issues.

Ductwork & Airflow Assessment: Identifies leaks or restrictions that waste energy and reduce comfort.

Heating System Safety Checks: Reviews burners, heat exchangers, and venting for safe operation.

Refrigeration-Specific Checks (for businesses): Reviews temperatures, door gaskets, defrost cycles, and alarms to protect inventory.

And when those routine steps are overlooked, the effects tend to show up in ways most people don’t expect.

The Hidden Costs of Skipping Maintenance

Skipping HVAC maintenance may seem harmless in the moment, but the impact shows up quietly, through higher bills, avoidable repairs, and equipment that wears out faster than it should. Most of these costs don’t appear right away, which is why they’re easy to underestimate.

Here’s what typically happens when routine maintenance gets pushed off:

Issue | What It Really Means |

|---|---|

Rising Energy Bills | Dust, blockages, and worn parts force the system to use more power to do the same job. |

Surprise Repair Costs | Small issues that would’ve been cheap to fix turn into urgent, expensive breakdowns. |

Shorter Equipment Lifespan | Systems run under strain, leading to earlier-than-expected replacements. |

Inconsistent Comfort | Uneven temperatures, weak airflow, or unstable refrigeration performance. |

Business Disruptions | For commercial spaces, downtime affects customers, staff, and operations. |

Higher Total Cost of Ownership | More energy + more repairs + earlier replacement = paying more over time. |

All of this makes one thing clear: staying on top of maintenance isn’t just about avoiding problems; it’s an investment. And like any investment, it has a return.

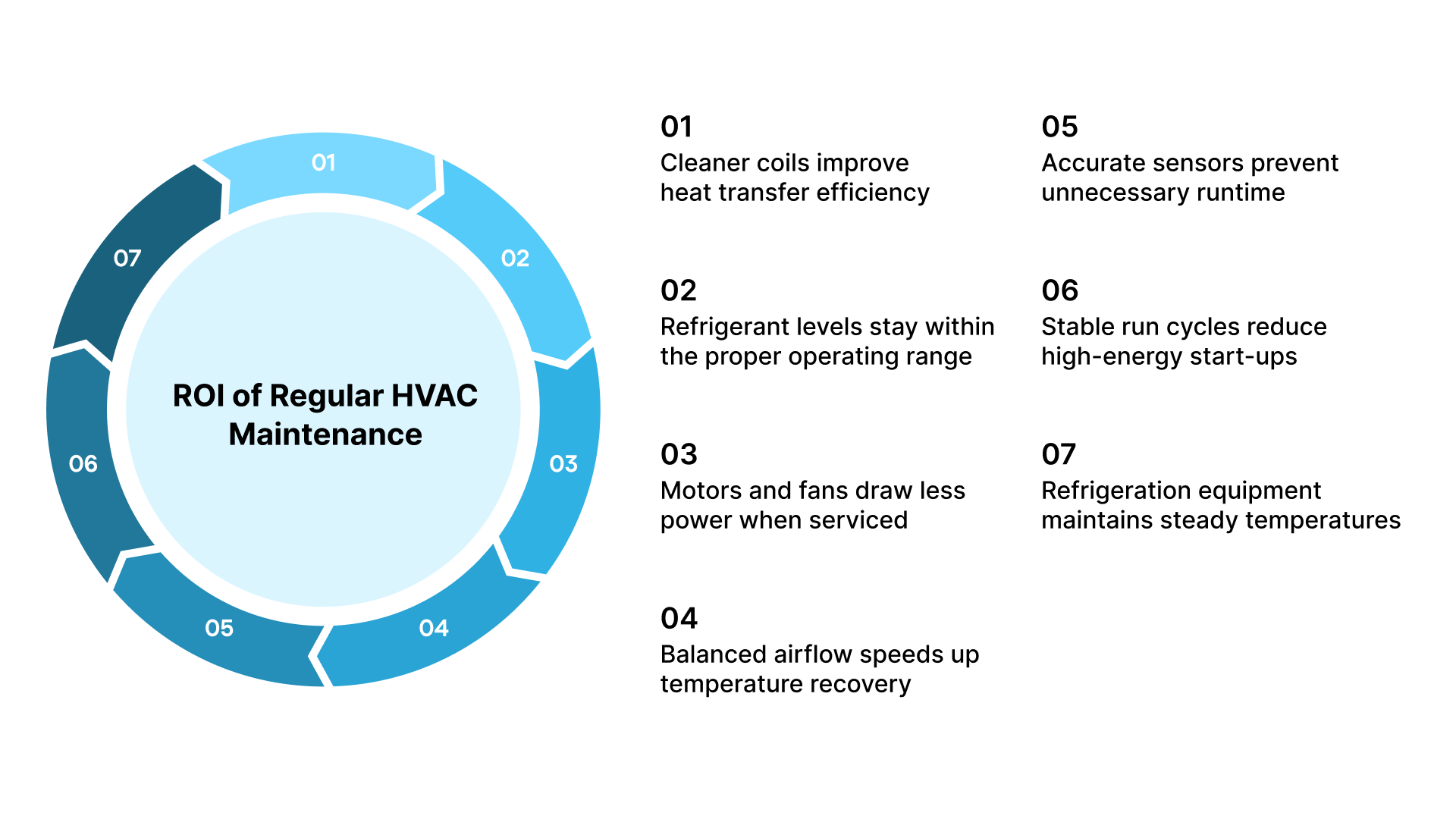

The ROI of Regular HVAC Maintenance

A broad 2025 industry review found that organizations implementing planned maintenance achieved 5–20 % annual energy savings compared to reactive servicing. That kind of gap adds up quickly, especially in places where cooling systems run long hours, and energy use is already high.

With numbers like that, the return on regular HVAC maintenance becomes hard to ignore. Here’s where those savings really come from:

Cleaner coils improve heat transfer efficiency

When coils can move heat properly, the system reaches the set temperature faster. Shorter run times directly lower energy use and monthly bills.Refrigerant levels stay within the proper operating range

A correctly charged system avoids the extra strain that increases power consumption. This reduces operating costs and helps prevent compressor failures, which are expensive to repair.Motors and fans draw less power when serviced

Clean, lubricated, and balanced motors run with the correct load. They consume less electricity and experience less wear, thereby lowering both energy costs and long-term repair costs.Balanced airflow speeds up temperature recovery

Good airflow allows the system to cool or heat a space quickly. Faster cycles mean shorter total runtime, which translates directly into lower energy costs.Accurate sensors prevent unnecessary runtime

When thermostats and sensors read temperatures correctly, the system shuts off at the right time. This avoids excess runtime and saves energy while keeping the space comfortable.Stable run cycles reduce high-energy start-ups

Preventing short cycling keeps the system from repeatedly starting and stopping. Fewer start-ups reduce energy spikes and protect components, which lowers repair costs over the life of the system.Refrigeration equipment maintains steady temperatures

Consistent temperature control reduces how often commercial refrigeration cycles. This cuts down on energy use and helps protect inventory, which is a direct financial benefit for businesses.

At this point, the only thing left to consider is how maintenance changes when you move from a home setting to a business setting.

Commercial vs Residential: What Changes in Maintenance Needs

Residential and commercial systems may look similar, but the stakes aren’t. A skipped tune-up at home is an inconvenience. In a business, it can interrupt operations or put inventory at risk.

To understand how that plays out in practical terms, here is how maintenance needs shift between the two.

Area | Residential HVAC | Commercial HVAC / Refrigeration |

|---|---|---|

Daily Run Time | Moderate, mostly tied to family routines | High and consistent, often running all day for customers and staff |

System Load | Designed for steady home comfort | Handles larger spaces, higher occupancy, and frequent door openings |

Maintenance Frequency | Seasonal tune-ups are typically enough | More frequent servicing, especially for kitchens, retail, and refrigeration |

Failure Impact | Discomfort and temporary inconvenience | Lost revenue, compliance issues, and potential product spoilage |

Component Stress | Standard motors, coils, and airflow demands | Larger compressors, rooftop units, walk-ins, and heavier cycling |

Response Time Needed | Usually flexible within a day or two | Often urgent, especially during business hours or for cold storage |

Operational Priority | Personal comfort and energy savings | Customer experience, staff productivity, equipment protection, and food safety |

Cost of Downtime | Mostly personal frustration | Measurable operational loss that compounds by the hour |

Once you know what your system requires, it helps to recognize the early signals that something isn’t running as it should.

Early Warning Signs Your HVAC System Is Headed for Trouble

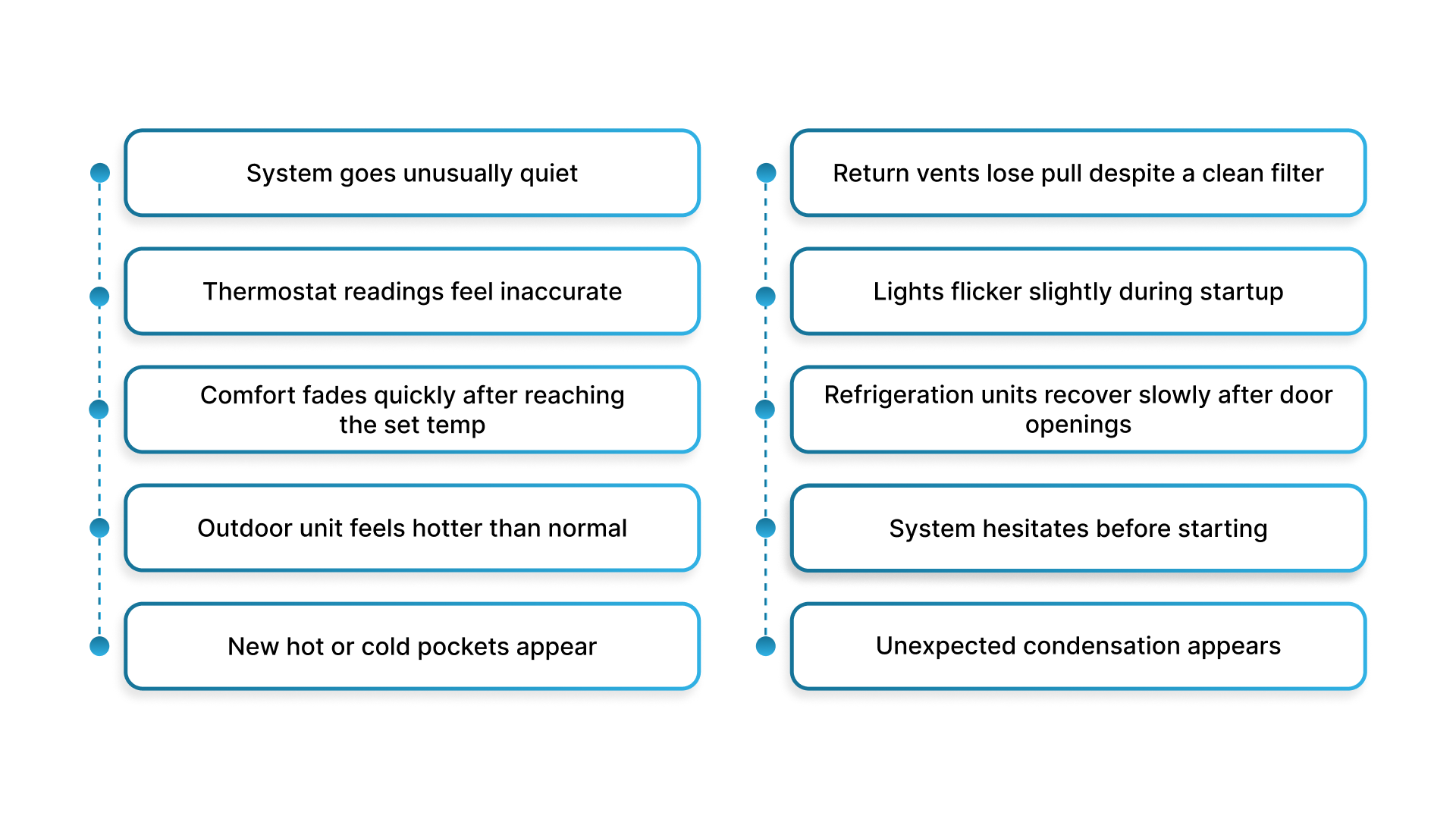

Most HVAC problems don’t start with a full breakdown. They start with small shifts you barely notice. Catching these early is what separates a simple tune-up from an expensive repair later.

Below are the early signals worth paying attention to before they turn into real trouble.

System goes unusually quiet: A sudden drop in normal operating noise can mean the blower or compressor isn’t cycling correctly.

Thermostat readings feel inaccurate: When the displayed temperature no longer matches how the space actually feels, sensors or controls may be drifting.

Comfort fades quickly after reaching the set temp: The system hits the target but cannot maintain it, which signals declining performance or airflow imbalance.

Outdoor unit feels hotter than normal: Excess heat on the condenser casing often points to airflow restriction or early refrigerant-side issues.

New hot or cold pockets appear: Temperature shifts in areas that were previously consistent indicate developing duct leaks or airflow disruption.

Return vents lose pull despite a clean filter: This usually means the blower motor or fan assembly is starting to weaken.

Lights flicker slightly during startup: Subtle dips in lighting can be an early sign of electrical strain or a compressor drawing too much power.

Refrigeration units recover slowly after door openings: For businesses, slow temperature rebound is often the first sign of declining cooling capacity.

System hesitates before starting: A delay between thermostat signaling and system activation points to early relay or control board issues.

Unexpected condensation appears: Moisture on vents, windows, or nearby walls can indicate humidity control problems or drain line restrictions.

And once those warning signs show up, that’s when a professional tune-up from a trusted local team really makes the difference.

What a Professional Tune-Up Looks Like

A basic filter change is easy, but the moment you step beyond that, HVAC systems in Texas work under conditions that demand trained eyes. Units deal with long cooling seasons, high humidity, and constant cycling; all of which put stress on coils, motors, refrigerant lines, and electrical components.

That’s why a professional tune-up matters. Central Air & Refrigeration is equipped to service air conditioners, heat pumps, furnaces, and commercial refrigeration systems. The technicians don’t just “check if it works.” They identify early inefficiencies, safety issues, and wear that most homeowners or business owners won’t catch until the system fails.

Here’s what a professional tune-up typically looks like when handled by a team that specializes in both residential and commercial HVAC systems:

AC tune-ups: Restore airflow, improve cooling performance, and reduce strain on the system.

Heating system checkups: Ensure furnaces and heaters run safely and reliably before seasonal changes.

Heat pump maintenance: Keep year-round heating and cooling efficient with proper inspections and adjustments.

Commercial HVAC servicing: Maintain rooftop units and commercial systems for consistent comfort during business hours.

Refrigeration performance checks: Support businesses by verifying cooling stability in walk-ins, coolers, and freezers.

Emergency HVAC support: Respond quickly to system stress or failure to prevent bigger issues.

Even with consistent maintenance, every system reaches a point where repairs stop making financial sense.

When Repair Isn’t Enough: How to Evaluate Replacement?

Some HVAC issues can be fixed. Others keep reappearing because the system is reaching the end of its usable life. Knowing the difference helps you avoid pouring money into a unit that can’t deliver reliable performance anymore.

Here are the clearest indicators that replacement may be the more practical choice.

Repairs stop lasting

If a repair works for a few weeks or months and the same issue returns, it usually means the underlying components are deteriorating, not just malfunctioning.The system struggles on normal days, not just the hot ones

When cooling or heating becomes weak, even during mild weather, it indicates the equipment can no longer meet basic load demands.The system runs almost nonstop

Continuous cycling, even when the temperature difference is small, signals declining capacity or failing internal parts.Airflow keeps dropping even after maintenance

If airflow feels weaker after coil cleaning, filter changes, and blower checks, it’s often a sign the system is losing mechanical strength.Certain rooms never reach the right temperature anymore

Persistent hot or cold spots, especially in rooms that used to be stable, point to a system that can no longer push conditioned air effectively.You hear new mechanical noises that don’t go away

Grinding, rattling, or compressor strain noises that return after servicing usually mean parts are wearing out, not malfunctioning.Your outdoor unit overheats often

If the condenser is hot to the touch or shuts off under load, it indicates the compressor is struggling to keep up.Your breaker trips when the system starts up

Breaker trips during start-up indicate the system is drawing more current than it should, a common sign of end-of-life.The thermostat is fine, but the temperature still drifts

If the thermostat has been replaced or recalibrated and the system still can’t hold a steady temperature, internal capacity is dropping.You’re repairing different components in the same season

When unrelated parts start failing one after another, the system is aging as a whole, not in isolated areas.

Final Takeaway

Your next smart move is simple: take a clear look at how your HVAC system is performing today. Small signs of strain often show up long before a complete breakdown, and staying ahead of them is what keeps costs low and comfort steady.

The systems that run the longest and stay the most efficient aren’t the ones with the latest features; they’re the ones supported by consistent, expert maintenance.

At Central Air & Refrigeration, HVAC care isn’t a one-off fix. Our team focuses on keeping systems stable, efficient, and predictable so you’re not stuck reacting to problems after they’ve become expensive.

Ready to talk through your HVAC needs or get expert clarity on your system’s condition? Connect with Central Air & Refrigeration anytime.

FAQs

1. How often should I schedule HVAC maintenance?

Most systems benefit from a professional tune-up at least once a year. Homes typically do well with annual service, while businesses with higher usage or commercial refrigeration often need maintenance twice a year or more.

2. Can regular HVAC maintenance really lower my energy bills?

Yes. When airflow is clear, refrigerant levels are correct, and motors aren’t under strain, your system uses less electricity to reach the same temperature. That translates into lower monthly bills.

3. What’s the difference between maintenance for homes and businesses?

Residential systems run based on personal use, but commercial systems operate longer hours and often support larger spaces, storefronts, or refrigeration. That means they require more frequent and more detailed maintenance.

4. When should I consider replacing my HVAC system instead of repairing it?

Replacement becomes worth considering when repairs stop lasting, airflow keeps declining, major components fail, or the system struggles even on mild days. These are signs that the unit is losing overall capacity.

5. What should I expect during a professional tune-up?

A proper tune-up includes checking filters, coils, refrigerant levels, electrical components, motors, sensors, drains, and overall system performance. The goal is to catch issues early and keep the system running efficiently.